液体设备模块

INOXPA是食品、乳制品、化工和制药工业用机器和设备的制造商。我们的工艺设备和系统适用于各种类型的应用和产品。

-

MCR

Counter-Rotating Blenders

Counter-rotating blenders are used for mixing and homogenizing dispersed products at a controlled temperature with an optimum performance, regardless of the product viscosity。

-

Bioreactor

The microbial fermentation is the most applied method in biotechnology, and nowadays it is distinguished by innumerable applications. An example of this is the industrial scale production of erythromycin, antibiotic obtained from Saccharopolyspora erythraea under aerobic conditions. Vitamins like riboflavin, beta carotene and vitamin B12 is also produced industrially by microbial fermentation.。

-

发酵产线

INOXPA has developed equipment to enable simple and efficient sourdough production. Sourdough is used to make traditional products on an industrial scale.。

-

SLES-DE-10

SLES Dilution System

Sodium Lauryl Ether Sulphate (SLES) is a surfactant widely used for the manufacture of cleaning products, soaps, shampoos and even toothpaste.。

-

CMC

Mixing System

The CMC mixing unit is a skid designed for a fast dispersion of hydrocolloid products such as carboxymethylcellulose (CMC), flours, carbopol, pectin, and guar or xanthan gum。

-

CMC-ATEX

System for the production of hydroalcoholic gel

The CMC mixing unit is a system designed for a fast dispersion of hydrocolloid products such as carboxymethylcellulose (CMC), flours, carbopol, pectin, and guar or xanthan gum. 。

-

ViscoMix

Mixing of Viscous Products

The range of VISCOMIX equipment is intended for production of highly viscous pharmaceutical products.。

-

LiquidMix

Mixing of Low Viscous Liquids

LIQUIDMIX is a range of equipment intended for the production of low viscous pharmaceutical products (water- or oil-based).。

-

SolidMix

Solid-Liquid Mixing

The solid/liquid blender is designed for the dissolution of solids in the applications of the food-processing, cosmetics, pharmaceutical and chemical industries.。

-

MFL

Maturing / Fermenting Unit

The Maturing / Fermenting Unit is a tank which allows milk to be heated and also cooled, with the aim in mind to pasteurize (heat) the product and control its fermentation (cool)。

-

Bread rework plant

INOXPA has designed equipment for the rework of bread scrap. Once reprocessed, the resulting bread “cream” can be added to a recipe or used in a sourdough production reactor. This skid is designed to dissolve 25% reworked bread in 75% water, delivering a mildly viscous homogeneous product (around 250 cP).。

-

SilPig

Product Recovery System

The PIG system is ideal for the recovery of any product remaining in a pipeline at the end of the transfer process. As this product can be of a high value the PIG system recovers the product removing it from the pipelines and preparing the pipeline for a CIP process.。

-

SteriPig

Product Recovery System

The PIG system is ideal for the recovery of any product remaining in a pipeline at the end of the transfer process. As this product can be of a high value the PIG system recovers the product removing it from the pipelines and preparing the pipeline for a CIP process.。

-

CIP

Automatic Static System

Hygiene is such a vital factor during food processing that it should be considered as one of the production process steps. Incorrect cleaning in the food industry can lead to the loss of an entire day’s production and directly affect the end product’s quality.。

-

CIP

Manual Mobile System

Hygiene is such a vital factor during food processing that it should be considered as one of the production process steps. Incorrect cleaning in the food industry can lead to the loss of an entire day’s production and directly affect the end product’s quality.。

-

CIP

Automatic Mobile System

Hygiene is such a vital factor during food processing that it should be considered as one of the production process steps. Incorrect cleaning in the food industry can lead to the loss of an entire day’s production and directly affect the end product’s quality.。

-

CIP ph

Skid Mounted Units

Hygiene is an essential part of the processes of the food processing, cosmetics, pharmaceutical industries as a correct cleaning of all the elements is required (tanks, pipes, pumps, etc.). In addition, the last sterilization stage is commonly required in the pharmaceutical industry. We offer automated CIP/SIP units correctly selected and customized to guarantee a controlled cleaning and/or sterilization and an optimum efficiency without having to disassemble the process plants. 。

-

Bertoli

High pressure homogenisers

On joining the Interpump Group, INOXPA became the distributor in Spain, Portugal, Russia, Colombia, and South Africa for its sister company, Bertoli。

-

离心分离器

离心分离器用于从液体中分离固体或将液体内不同密度的成分进行分离。

-

KFA

Horizontal element kieselgur filters

Filters mounted on wheels up to 30 m2 filtering surface.Filtering stations (unmovable) from 10 to 30 m2.Unit entirely stainless steel AISI 304 made.Variable flow dosing pump. Lighted up inlet and outlet sight glasses.Horizontal screens design prevents the cake fall from eventual electrical cuts, even for long energy interruptions. Use of last filtering screen as scavenger filter.Centrifugal cake discharge system.Washing of vessel inside performed by sprayers.Filtering screens easy inspection by removing the filter’s upper cover (our centrifugal motor system is located under the vessel chamber for rapid maintenance).。

-

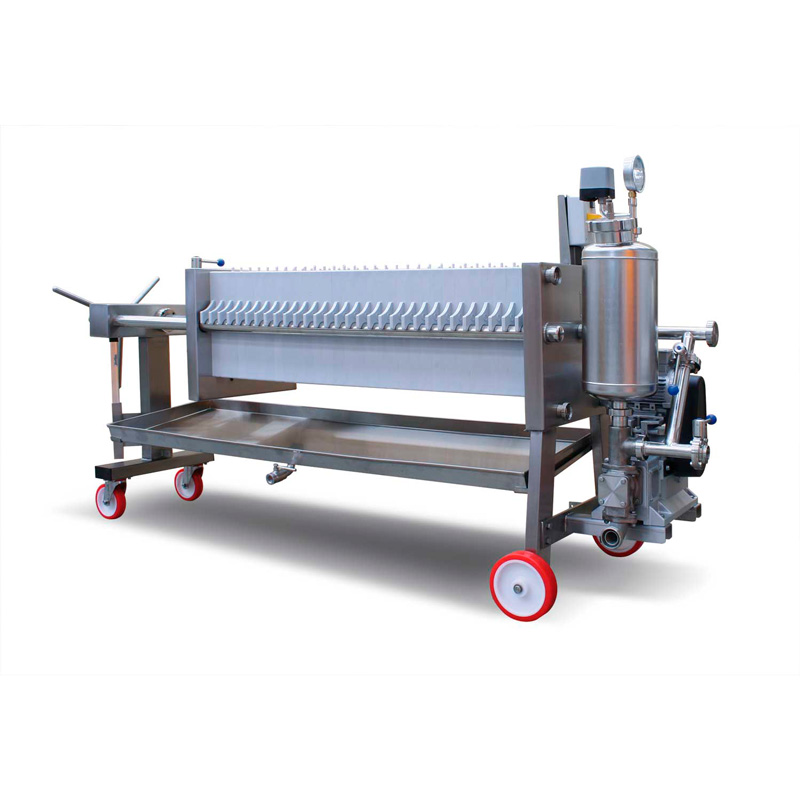

FC

Sheet filter

Filtering unit in stainless steel AISI 304 made.All plates are suitable for the use of cardboards at low working pressure.Valves and fittings in stainless steel AISI 304 made.Pressure gauges and sight-glasses.Sample-tap.Filtering plates package by adjustable mechanical screw.Drip collecting drip in stainless steel made.。

-

AM

Less filter

This is a multi-functions filter, quite versatile, commonly used for the filtration of many products like fermented and unfermented lees, young wines, wine-musts and, not last, it is a type of filter properly indicated to process chemical and industrial fluids in general.。

-

MQ

Vacuum rotary filters

Completely made in stainless steel AISI 304 the filtering screen is in 316 SS.Centralized control panel.Automatic blade return at the end of the filtration cycle.D.E. tank equipped with mixer.Filtered liquid manifold completely separated from the air manifold.Possibility of filtering the residual liquid.Drum easily inspectable through a manhole.Filtration tank.Vacuum pump cooling system equipped with buffer tank to reduce waterconsumption.。

-

CF

Crossflow filter

CF CROSSFLOW FILTERS belong to the highest quality construction of INOXPA’s range of filters, equipped with a special tubular capillary membranes made in polypropylene, ideally suitable for filtering wines, vinegar, juices and, in general, liquids related to the Food Industry.。

-

UHT

Sterilisation of liquid and low-viscosity food products

Ultra-High-Temperature (UHT) treatment is a processing technology employed to kill microbial spores in order to guarantee safe and stable shelf life to food products by exposing them to high temperature, usually between 135°C and 145°C, over a very short time period ranging from 2 to 5 seconds.The products treated in such a way can be maintained under unrefrigerated conditions for months.。

-

HTST

Pasteuriser

Pasteurisation of liquid and low-viscosity foods High-Temperature-Short-Time (HTST) thermal treatment, also named pasteurisation, is a processing technology based on the effect that the exposure to high temperature (70-100°C) for a certain time (15-300 sec.) has on food products. Such thermal treatment is employed to eliminate pathogens, to make the product safe for consumption and extend its shelf life. Microorganisms and enzymes that are responsible for food spoilage are either destroyed or deactivated even though most bacteria spores can be only killed by higher temperature, using UHT processing technology.。